How migration works

Process engineering systems, often based on automation technology from the late 1990s or early 2000s, need an innovation boost to remain competitive. Digitalization offers opportunities for more efficient working, better insight into processes, and additional functionalities. Furthermore, the migration towards Ethernet-based communication promises greater openness and higher transmission speed. Consumers are increasingly thinking online. However, process automation still requires systematic thinking and a pragmatic approach. The NAMUR Open Architecture (NOA) allows for the installation of additional sensor technology and monitoring elements, such as machine learning, artificial intelligence, and cloud services, without disrupting ongoing system operation.

Cooperation between OPAF and NAMUR

Open Process Automation (OPAF) is based on the idea of a modular IT world with process-oriented systems and long-term availability. Moreover, it has developed into an internationally active consortium of renowned system operators, technology manufacturers, standardization organizations, and software companies, collaborating with NAMUR for pilot projects and industry expertise.

Axioline F I/O system for implementing the NOA side channel…

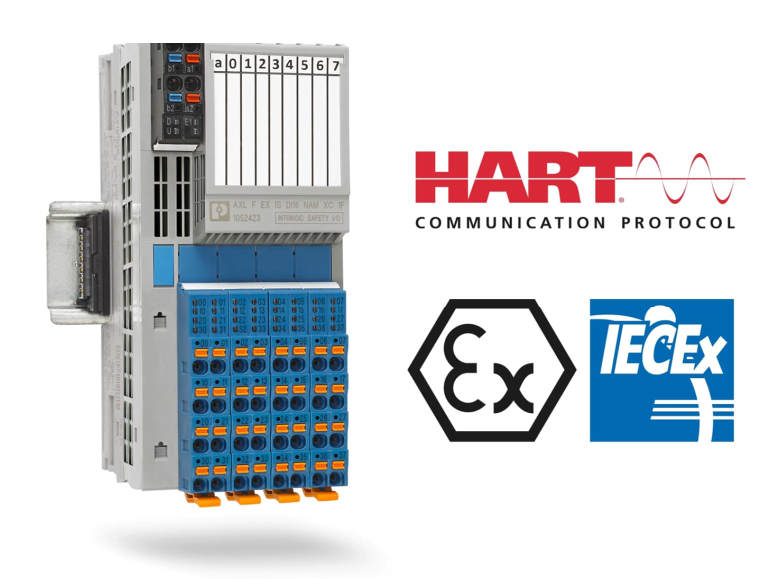

In addition, the Axioline F I/O product family and PLCnext Technology controllers are used in pilot projects. This modular system, originally designed for factory automation, can implement NOA side channels or data diodes. Since 2020, the portfolio has also included intrinsically safe I/O modules for NAMUR sensor technology, HART communication, and valve controllers.

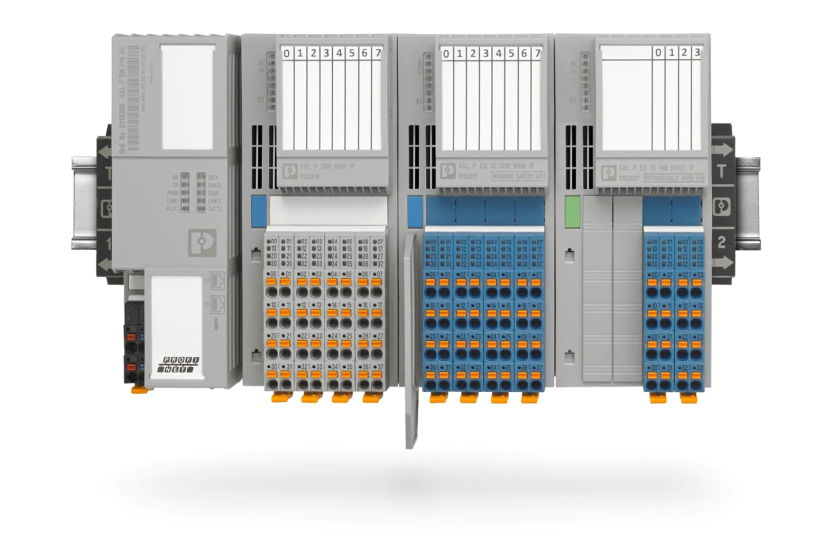

…and Axioline P with proxy functionality

Phoenix Contact introduced the Axioline P, a high-availability I/O system for process automation, at Achema 2018. The system offers both conventional I/O modules and Profibus PA proxy functionality, allowing hot-swap and dynamic reconfiguration. Furthermore, it can integrate up to eight Profibus PA segments in one Profinet I/O station, supporting 10/100 Mbps Ethernet transmission. The Axioline P proxies also provide redundancy, shielding, and 14 watts of power per segment. The Phoenix Contact portfolio includes I/O modules with and without intrinsic safety for every applications.

Integration of the intrinsically safe power supply into the modules

Phoenix Contact has introduced intrinsically safe Axioline F and Axioline P modules in the XC Ex series, which eliminate the need for intrinsically safe power supply modules. The Axioline F system is used in NAMUR automation and PLCnext Technology controllers. The Axioline P module supports Profinet S2 redundancy and is used in zone 2 installations to connect field devices that are mounted in zone 2 or 1. The modules have a black power supply connector and partition plates. A Modbus/TCP version version of the Axioline P family will be launched in 2024, opening up new possibilities in open process applications.

Connection of up to eight Profibus PA segments

For migration, the Axioline P platform enables the connection of up to eight Profibus PA segments with high-power trunks and universal I/O connections into the field. It offers advantages in size and cost-effectiveness compared to previous designs. The intrinsically safe I/O modules provide greater flexibility. The first NOA and OPA pilot solutions were presented at the NAMUR Conference, and APL technology is predicted to be of great importance.

Learn more about process automation.