Full speed ahead

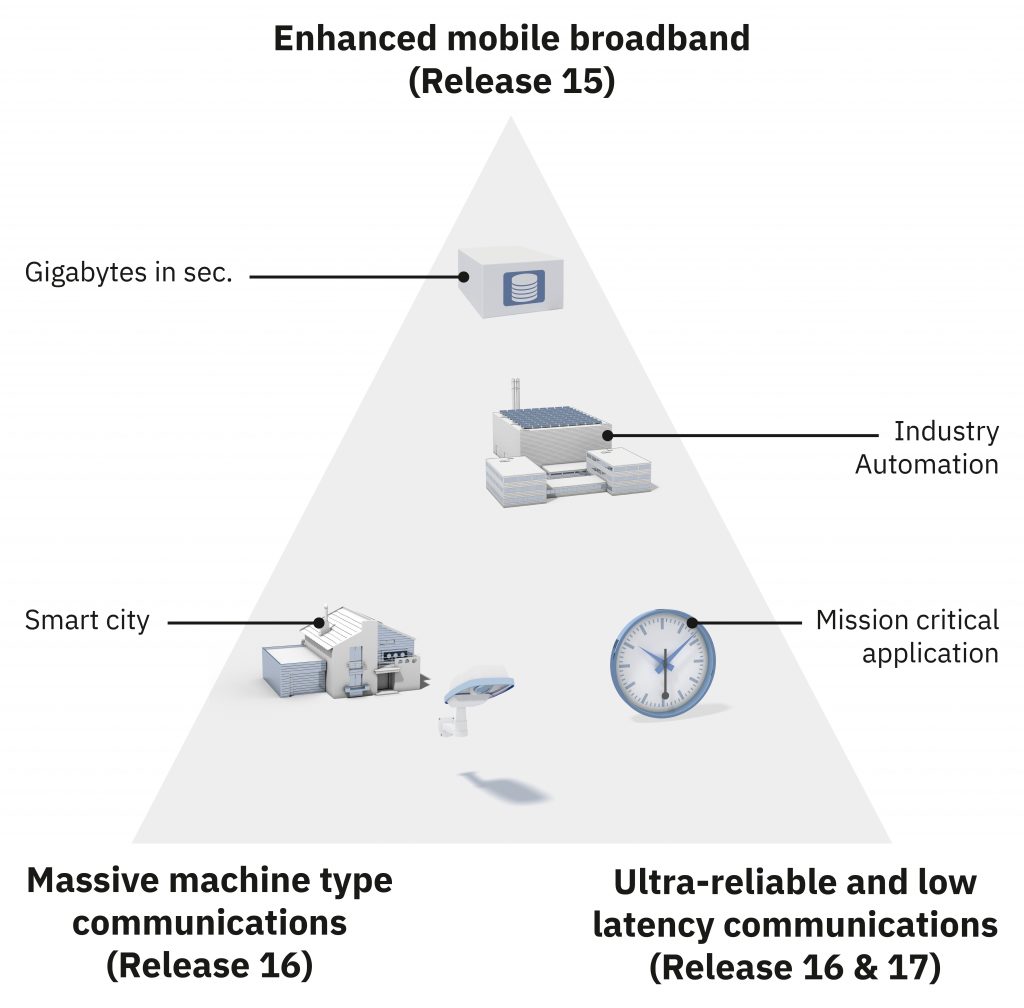

The next generation of 5G standard promises significant advancements in wireless industrial data exchange. Historically, cellular technology focused on consumer communication, but now it takes industry interests into account. The standardization also includes requirements for the Industrial Internet of Things (IIoT), such as Massive Machine Type Communications (mMTC) and time-critical communications (Ultra Reliable and Low Latency Communications). The Third Generation Partnership Project (3GPP) standardization organization has released several specifications, with the current functions expected in Release 18, set to be published in 2024. However, developing semiconductors, network technology, and products is expected to take at least two years.

Structure of private cellular networks

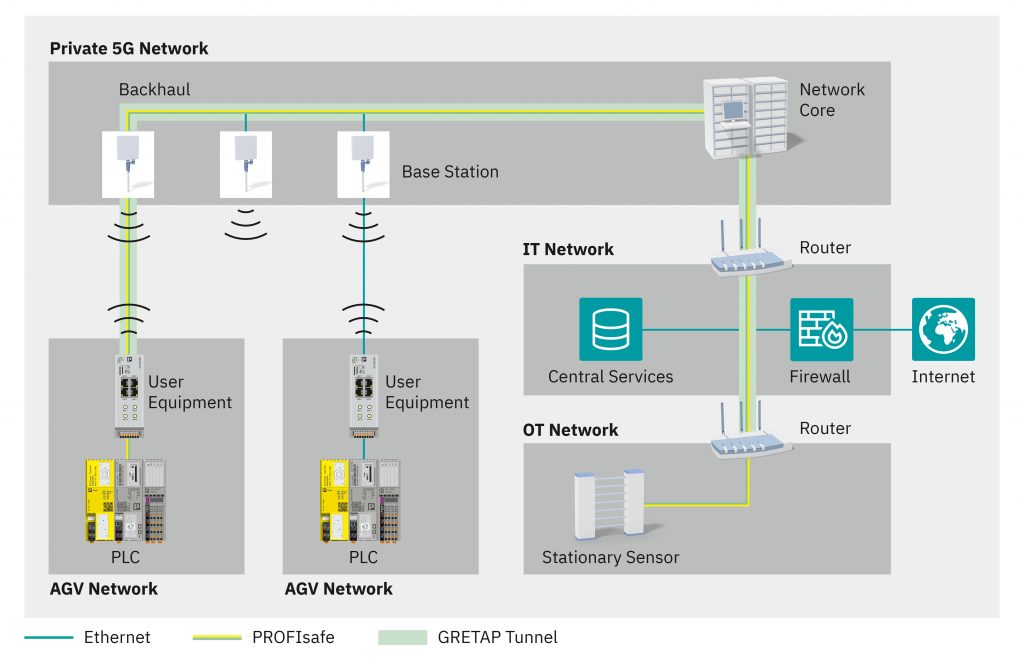

Private cellular networks, similar to public networks, use wireless communication between end devices and radio towers. These base stations connect to a central data center, which manages and authenticates connections. The network core, consisting of local 19-inch equipment, acts as the central communication element, routing user data and forwarding it to the internet. This ensures reliable communication with low latencies and high failsafe performance.

Low cabling overheads in wide-area networks

Private 5G networks use a licensed frequency band, allowing better control, efficiency, and prioritization of communication devices. This technology is beneficial in small areas with a large number of wireless devices and outdoor applications with fewer base stations. 5G can serve various applications across one infrastructure, including eMBB, video application, remote maintenance, AR, logistics, and on-site facility management. It also offers uRLLC functions for field communication, allowing robots to reassemble without adapting communication cabling. Automated guided vehicles can exchange data and outsource the intelligence of these devices to a central server system, reducing equipment costs and increasing scalability.

Forwarding small data packets quickly and reliably

The examples discussed above involve reliable data transmission from an AGV to safety sensors and other AGVs, allowing them to traverse hazardous areas at full speed without collisions. This is achieved through Profisafe protocol, a safety profile for the Profinet fieldbus. This communication is based on Layer 2 of the OSI reference model, with data exchanged via MAC addresses in a closed network. In a 5G network, routing is required due to the separate network of AGVs, robot cells, and production networks. Data is transmitted via a Layer 2 tunnel connecting the AGV’s network with another AGV’s network, encapsulating data into IP packets.

Falling costs as the number of private 5G networks increases

5G technology is promising for wireless industrial data exchange, but challenges remain. Current hardware is not suitable for uRLLC communication, and Profisafe transmission is feasible but not reliable. Hardware for later releases is under development to address latency spikes in AGV applications. As costs decrease, private 5G networks will increase for customized applications. However, wide-ranging projects demonstrate the variety of applications 5G can create, especially in uRLLC applications in AGVs and robotics, highlighting its potential in industrial communications.

Learn more about Industrial 5G and Safety-related PLCs for Profisafe.