Modern terminal block systems deliver high performance and are available in many versions but their installation and configuration are very laborious and time-consuming. This is where Phoenix Contact’s PTFIX distribution block system comes into place offering a variety of options for optimization.

There is always the challenge of making the wiring process fast, inexpensive, and as compact as possible. High-quality terminal block systems with different connection technologies and comprehensive accessories usually result in high-performance solutions. This is only possible if the connection quality and the selection is done right.

But how are we sure that the selected package is really the best option for the application? Wouldn’t something smaller and cheaper be better? And what about time? How much time does it take to install and wire my solution?

Choosing the right connection technology will save you a great deal of wiring time, and time is money. For example, opting for the spring cage connection instead of screw connection, helps you avoid torque range verification. Thus, saving on an expensive torque screwdriver.

Push-in direct-connection technology is the equivalent of a “digital” terminal point and delivers maximum time savings and connection reliability. The scenario is that it is either connected or not connected. Hence issues caused by the wrong torque for screw connections, do not occur here.

Space savings and flexibility – can the two go together?

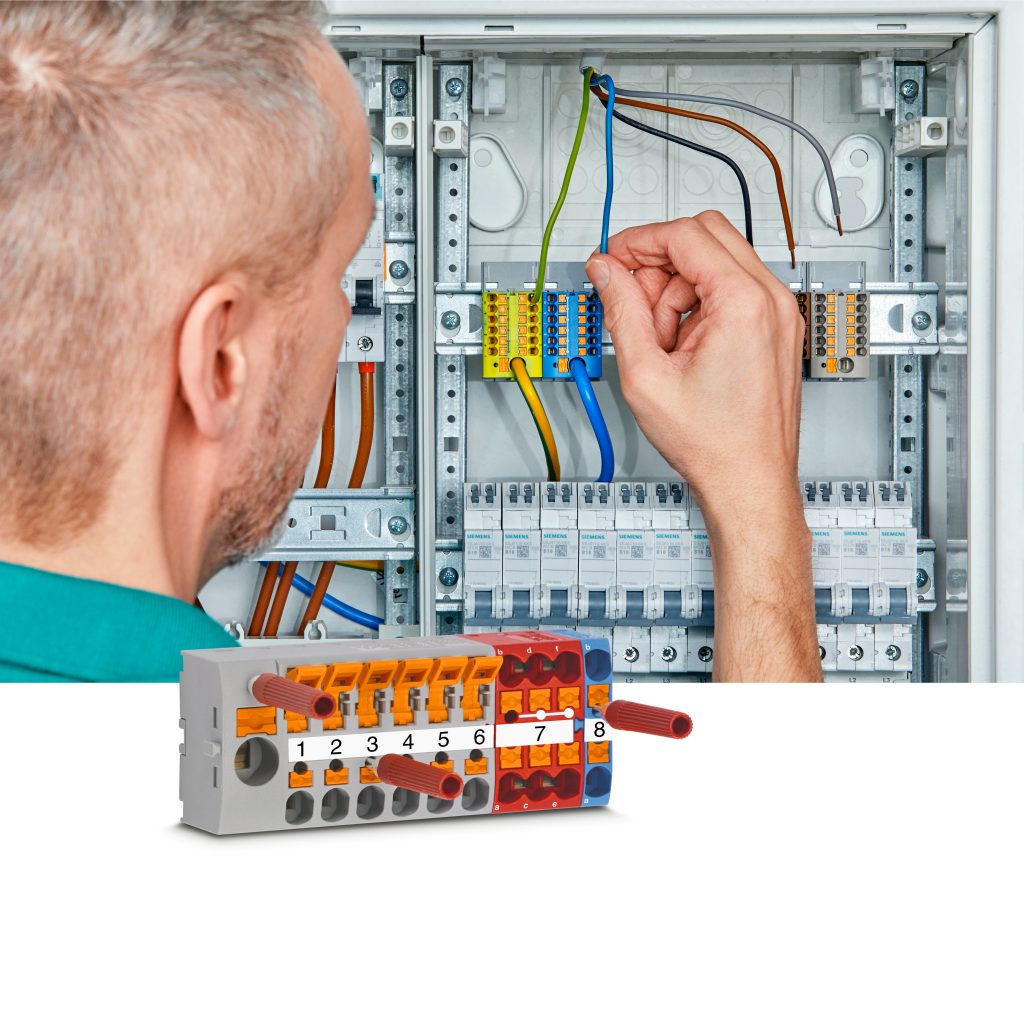

Phoenix Contact has created new possibilities for universal wiring with its PTFIX distribution block series. In creating small, easy-to-use solutions, the company reduces the scope of functions to an essential minimum. This makes it possible to fit base blocks with different adapters. You can mount them vertically or horizontally on all standard TH35 and TH15 DIN rails in accordance with IEC (DIN EN) 60715.

For projects that prioritize fast installation times, Phoenix Contact offers pre-assembled items that already include a mounting adapter. You can simply unpack, install, and wire them. To save more time, there is also a configurator to support you in finding the right solution for your application.

Monoblocks which have two connections, essentially reproduce the function of a feed-through terminal block. They enable distribution as well as individual signal wiring.

By using PTFIX, it is possible to implement very complex circuits in an extremely space-saving, flexible, and fast manner. It is the only one in the market that provides disconnection, testing, fuse protection, and connection of discrete components.

Disconnect function in miniature format

In machine building, controller manufacturing, and process technology, knife-disconnect terminal blocks are particularly suitable.

There are also two versions of PTFIX blocks with disconnect knives. They have the same number of available connections and connection cross-sections as the base block. Both versions have pre-installed disconnect knives in the disconnect zones. However, the two versions differ in how you can operate the knives.

The MT version features the familiar disconnect knives that you need to open with the aid of a screwdriver. While the PTFIX blocks with MTL disconnect knife can be opened without using a tool. Which is the preferred option for users who work in protected areas.

The PTFIX disconnect blocks comply with the harmonized standard IEC (DIN EN) 60998-2-2. They have also been tested in accordance with IEC (DIN EN) 60947-7-1 for 400V max. 20 A per disconnect zone.