Industrial DC grids are already a reality. Companies can implement and operate them today and benefit from their efficiency. Schaltbau in Munich and Phoenix Contact in Blomberg demonstrate this through best‑practice examples.

Continue readingYearly Archives: 2025

Wi-Fi 6E for applications with a large number of devices and small data packets

From |Increased efficiency and security

Demand for wireless communication in industrial environments is rising, but WLAN standards up to Wi‑Fi 5 face limits from interference and capacity. Wi‑Fi 6E expands the frequency spectrum with advanced technologies, enabling more efficient and secure data transmission.

Continue readingPhoenix Contact Trading LLC to Showcase Smart Manufacturing Innovations at Industrial Transformation Saudi Arabia 2025

From |Phoenix Contact is proud to announce its participation in the upcoming Industrial Transformation Exhibition, powered by Hannover Messe, taking place in just 10 days at the Riyadh International Convention & Exhibition Center. This premier event brings together global leaders in industrial automation, electrification, and digitalization to shape the future of smart manufacturing.

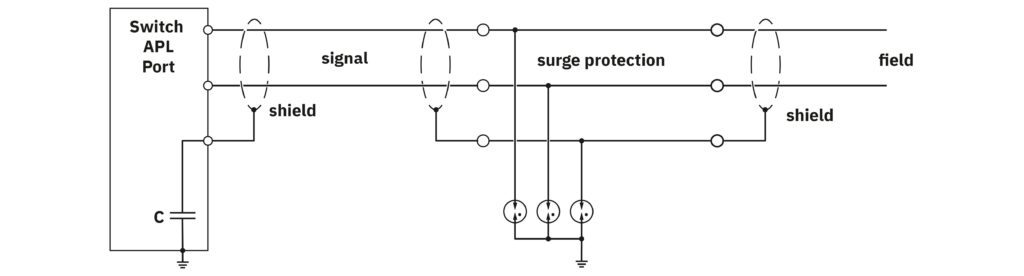

Continue readingHigh-availability Ethernet-APL with surge protection

From |The necessity of surge protection in process engineering systems

Surge protection and equipotential bonding are established in the process industry. In explosive areas, consistent bonding and, if needed, surge protection are essential. The APL products can be integrated into existing grounding and shielding concepts, where high-quality bonding ensures system availability. They allow cable shielding decoupling alongside classic one- or two-sided grounding. For field use requiring maximum failsafe performance possible, the trunk is implemented via fiber optics with an integrated SFP module, though RJ45 remains an option.

IEC 61643-21 extended with additional safety-related tests

From |Requirements on surge protective devices in signal processing networks further increased

Transient overvoltages can damage sensitive electronics in signal networks. Surge protective devices (SPDs) safeguard against these disturbances and maintain high system availability.

Continue readingIndividual configuration, precise and efficient identification

From |A digital solution for customer-specific marking solutions

Application-specific, standard-compliant identification is key to quality, safety, and availability in industrial plants. Yet evolving requirements, complex standards, and cost pressures pose challenges. Phoenix Contact shows how digital, customer-specific marking solutions support future-proof production.

Continue readingPush-X terminal blocks for semi-indirect and indirect measurement

From |The new flagship for transformer disconnect terminal blocks makes wiring and handling current and voltage transformers easier

Quick and easy direct-connection technology and automatic short-circuit switching enhance transformer secondary wiring and safety.

Continue readingBuilding control cabinets more efficiently with lean management

From |Tobol optimized its control cabinet production together with Phoenix Contact

Using lean methods, Tobol transformed its production from job-shop to flow-oriented, resulting in faster, more efficient output with minimal errors.

Continue readingSecurely connected with ease

From |How connector coding increases safety

The star fits in the star, the circle in the circle. This motor skills exercise teaches that only matching shapes connect. Similarly, mechanically coded connectors prevent mismatches, protecting both devices and users.

Whether plugging in a toaster at home, a USB-C phone charger, or an industrial PC, each system uses specific connector patterns to protect users. These patterns prevent incompatible connections, especially for power, signals, and data. While mismatched signal or data lines may fail to work, mixing them with power can damage devices and pose a danger to the user.

Continue readingWireless communication in automated transport systems

From |Reduced effort and higher availability with NearFi technology

Physical connections in moving factory applications are now obsolete no more downtime from worn contacts. Goods distribution systems, robots, and AGVs communicate wirelessly and efficiently. This isn’t the future; it’s happening now with Phoenix Contact’s NearFi technology.

Continue reading