Less maintenance effort thanks to contactless data and power transmission

SHL AG has been developing systems for automated grinding, polishing, and deburring since 1989. The company uses NearFi contactless power and real-time Ethernet solutions from Phoenix Contact for wear-free and maintenance-free communication. SHL’s systems include flexible robot cells, grinding, polishing, and deburring cells, as well as complete production cells. The company supplies users from various industries, including faucets, automotive crankshafts, and titanium and ceramic for medical applications. With 95 percent vertical integration, SHL reduces production costs through better cycle times. However, shorter cycle times and movements can lead to more wear, resulting in downtime.

Data exchange via slip ring was previously prone to interference and wear

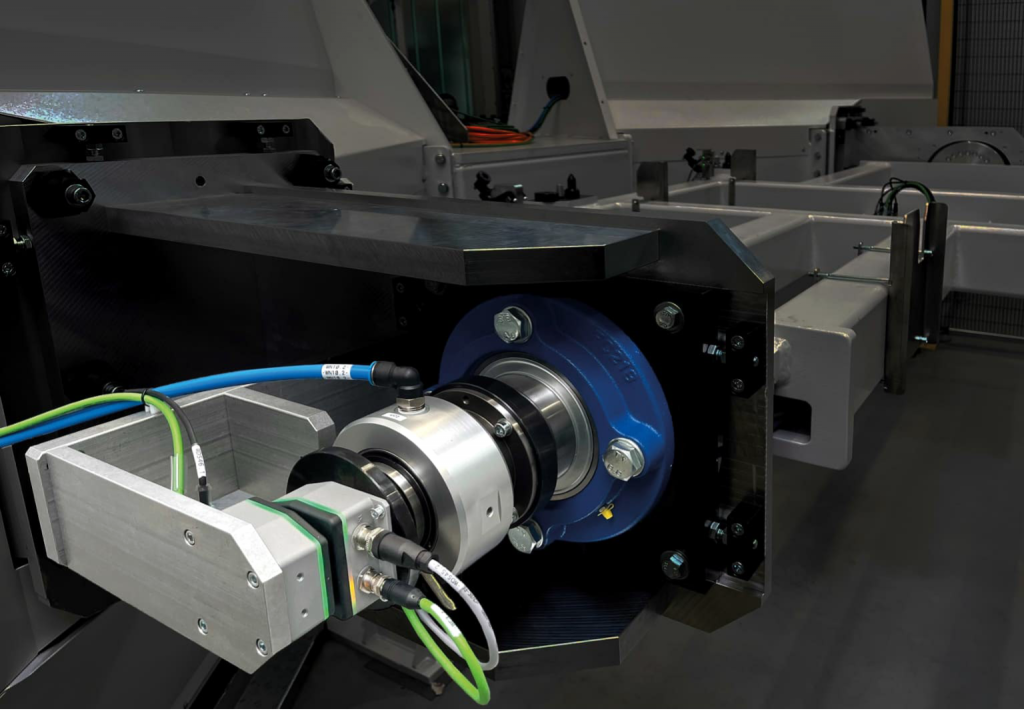

Surface processing requires workpieces to swivel 360 degrees, and rotary tables with swivel units are used. The system consists of three areas for the various processing steps: insertion onto the carrier, ithe initial processing of the workpiece by sanding robots with coarse grit, and finally processing by sanding robots with fine grit. The rotary table rotates the workpiece to the next processing station. Bernhard Mattes, Senior Director of Engineering at the Böttingen plant, introduced contactless NearFi technology for wireless data exchange, which is mounted on each rotary axis for the three endlessly rotating swivel units.

Simple startup without configuration effort

NearFi enables contactless data and power transmission using base and remote couplers that can be flexibly positioned without precise alignment. It reduces maintenance costs, enhances system availability, and simplifies startup with quick, configuration-free connection via 24V and Profinet cables, communicating Ethernet protocols at 100 Mbps full duplex.