Written by Andrew Ellis, Field Application Engineer

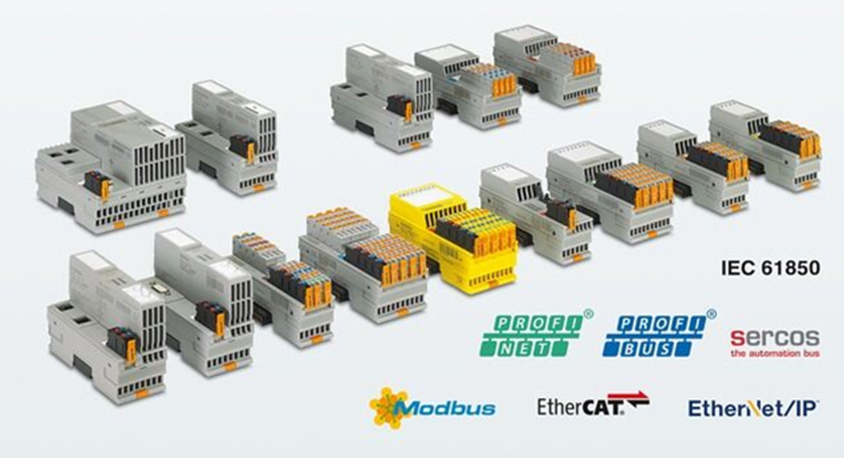

Whether in the control cabinet or in the field, whichever network you use…Phoenix Contact has experience providing a Remote I/O Solution. Whether it is our original Inline system, or if your application requires high speed, wide temperature range or just simplicity and reliability, it is covered with our Axioline system.

Both Ranges contain a variety of standard and special I/O as well as support for Safety using Safety Bridge and PROFISAFE.

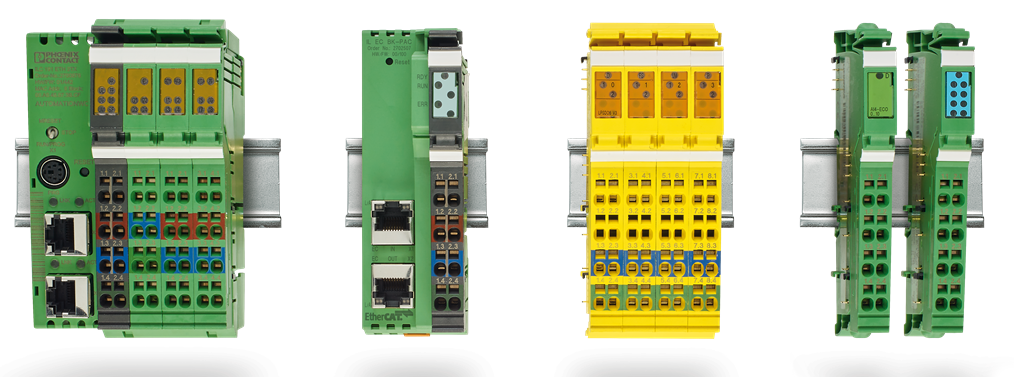

Inline – The original and still going strong.

Automate applications easily and cost-effectively with the Inline system consisting of PLCs, bus couplers, and I/Os for the control cabinet. Due to its flexibility, the automation and I/O system can be used in a large number of projects. Combined with the specifically developed programmable logic controllers, even complex automation processes can be developed systematically. Moreover, the open bus concept means that the system provides you with several options in various networks.

The Inline range is still being developed and updates so that existing and new systems are supported well into the future.

Axioline F – operates all leading networks: PROFINET, EtherNet/IP™, EtherCAT, sercos, Modbus TCP, PROFIBUS. IEC 61850 approved versions also available.

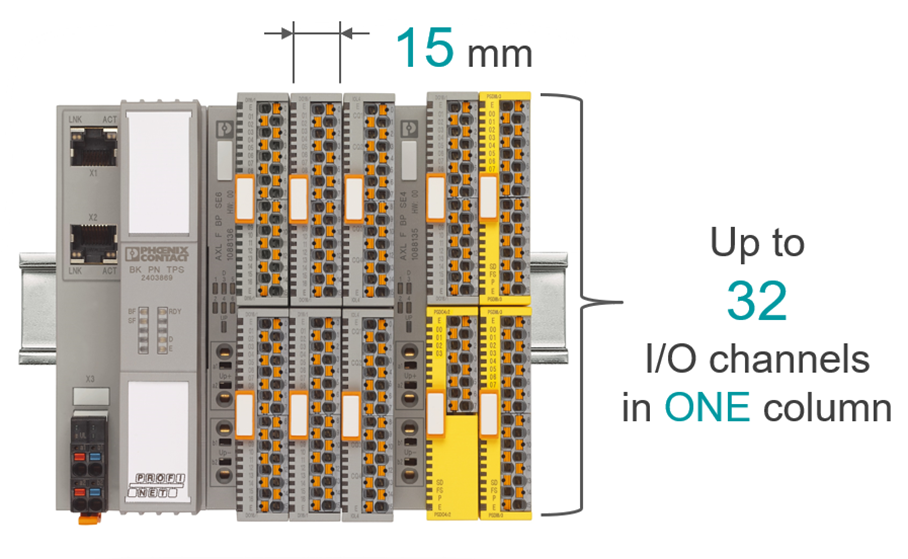

The Axioline F I/O range is rugged and compact. Using the latest technology in control and connectivity it saves you time and space in the control cabinet providing a flexible platform for all modern day automation applications.

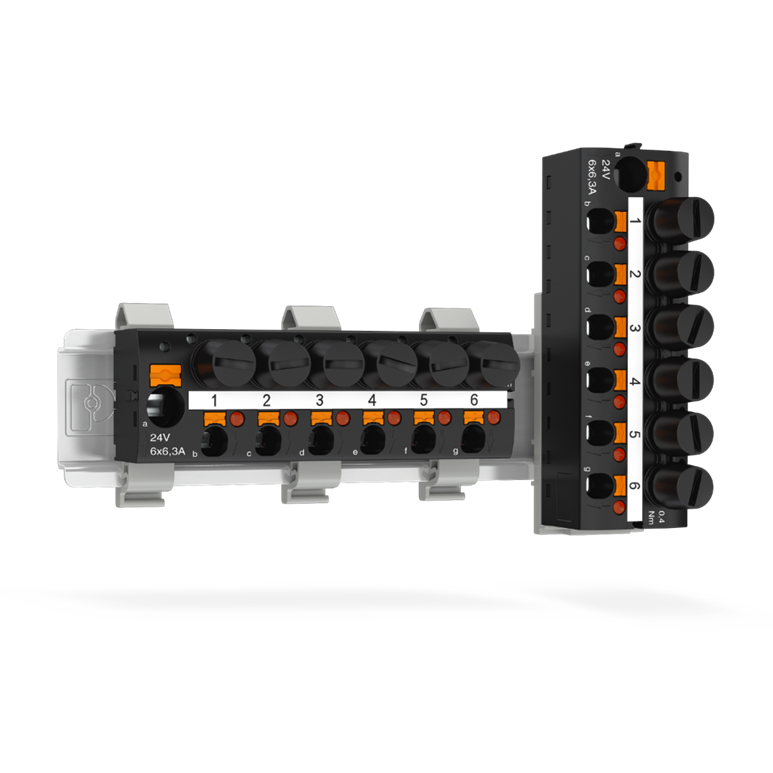

Axioline SE – With panel space, easy start-up and component costs being some of the major requirements of systems builders, the marketplace demands suppliers to react in order to help businesses maximise production and profits and minimise costs.

The Axioline Smart Element range is designed to combine with the comprehensive range of Axioline Fieldbus couplers and PLCs including the latest innovation in PLC systems, PLCnext Technology.

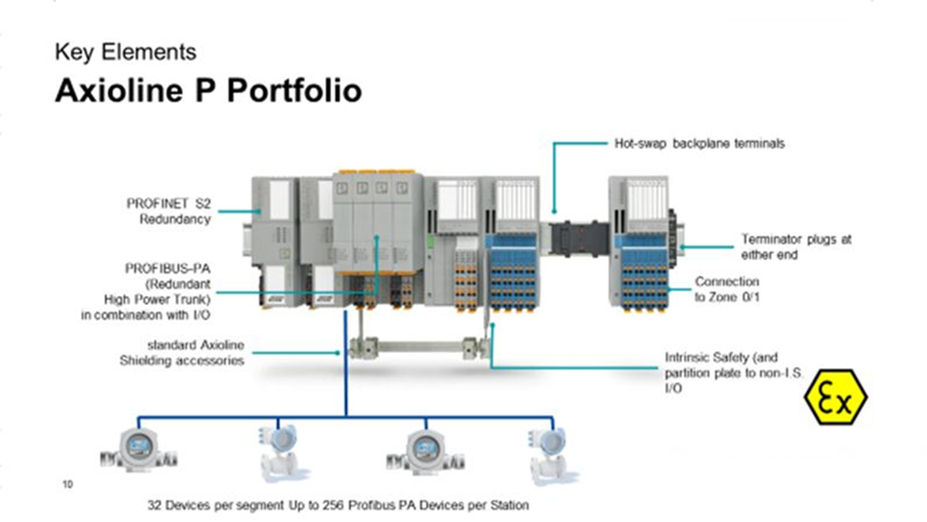

Axioline P – The AXK P BK PN – AF is a PROFINET bus coupler device which drills down directly to Profibus PA negating the need for the Profibus DP layer. Therefore, reducing infrastructure, system component and installation costs as well as streamlining overall system architecture.

The AXL P BK PN – AF Bus coupler features the following

- 8 Profibus PA Segments with High power trunk per Bus Coupler. Each segment can support 32 devices. Which means each coupler can support 256 Profibus PA devices.

- Dual redundant pluggable power supplies for each Profibus PA segment. Ensuring high availability, if required.

- The AXL P BK PN – AF Bus coupler supports PROFINET S2 redundancy. Once again providing the maximum of system availability.

- The AXL P BK PN – AF Bus coupler boasts a full complement of Hot swappable I/O that co-exist alongside the Profibus PA Segments on the AXL P BK PN – AF Bus coupler. Including Intrinsically safe digital and analog Inputs and Outputs, Supervised Inputs (Namur), Hart Inputs and Outputs.

For more information on our Remote I/O Solutions, or to discuss your application please contact Andrew on 07584514958 or email aellis@phoenixcontact.com