Happy Birthday to you, happy birthday to you, happy birthday dear QUIIII-INT, happy birthday to you!

This year marks 25 years since the first QUINT power supply was released. That’s back in 1996 when just 5 power supplies were released to the market. Fast forward to today and there are more than 100 QUINT products available with the QUINT4 being the most recent iteration.

So how have we seen the QUINT develop over this time?

Obviously, they have become smaller and more efficient, for example our second-gen QUINT 40A (only just discontinued) was the size of a small breeze block at a width of 240mm. Compare this to the QUINT4 version which is exactly half the width at 120mm.

The QUINT now packs many more technical features and benefits that make it the #1 choice for markets and applications where reliability and power resilience is key.

Some features that have been added and are now the norm are such things as:

- Boost Power, both dynamic (short term) or static (permanent)

- SFB – selective fuse breaking, a high current boost enabling fast tripping of breakers or even fuses.

- Better monitoring & diagnostics with configurable digital outputs and an analogue output

- High reliability and long lifetime, typically 15 years.

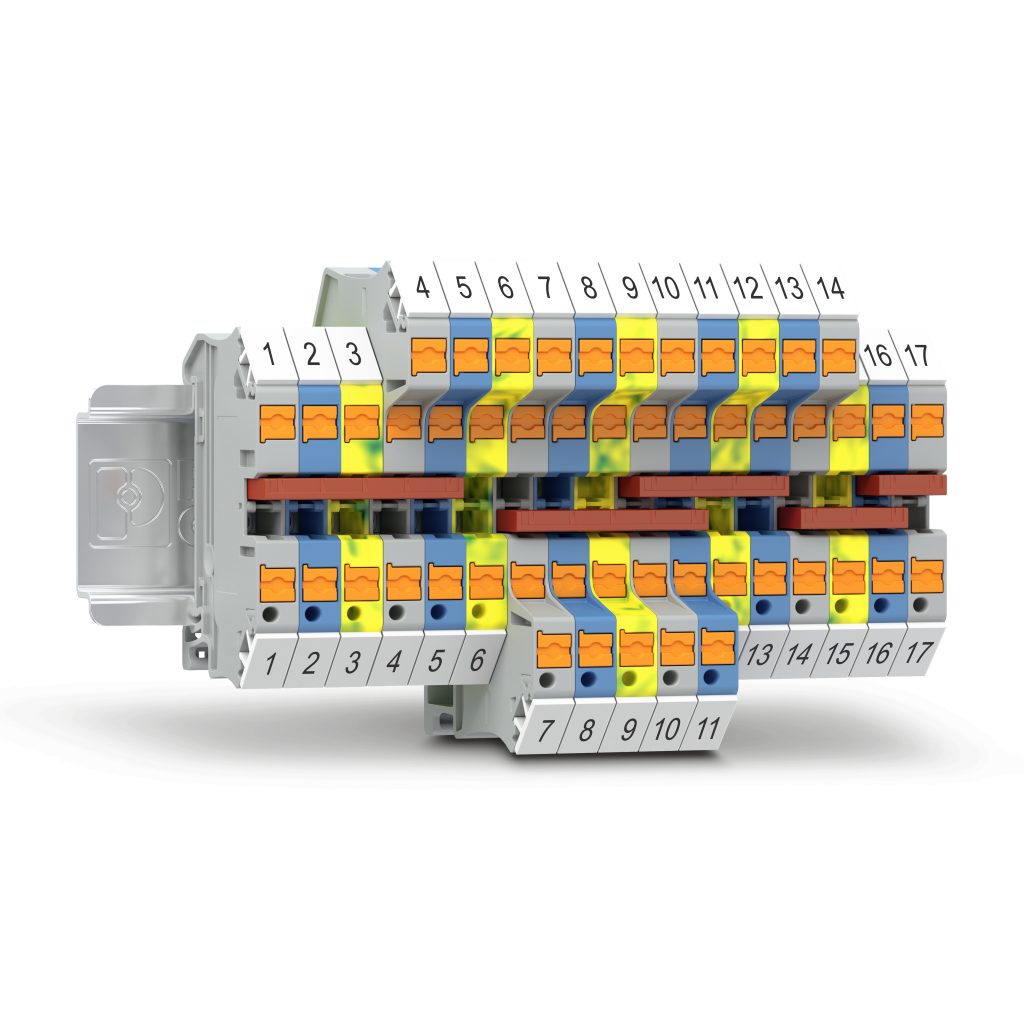

QUINT is not just a power supply range (available from 1A to 40 A), the range includes DC/DC converters, redundancy modules, uninterruptible power supplies and energy storage devices including various battery technologies, buffer and Cap modules.

The complete QUINT solution for maximum plant availability can be seen via the following link. Here you will find info on all the products under the QUINT banner including a live demo showing our intelligent communicative QUINT4 UPS.

The near future will see more development in the area of communication, including IO Link and easier integration with complementary Phoenix Contact systems such as electronic circuit breakers. I would not be surprised if a fifth generation QUINT is not already under development.

The QUINT power system is part of the COMPLETE line system.

For more info contact Mark on 07717 335477 or email mlloyd@phoenixcontact.com