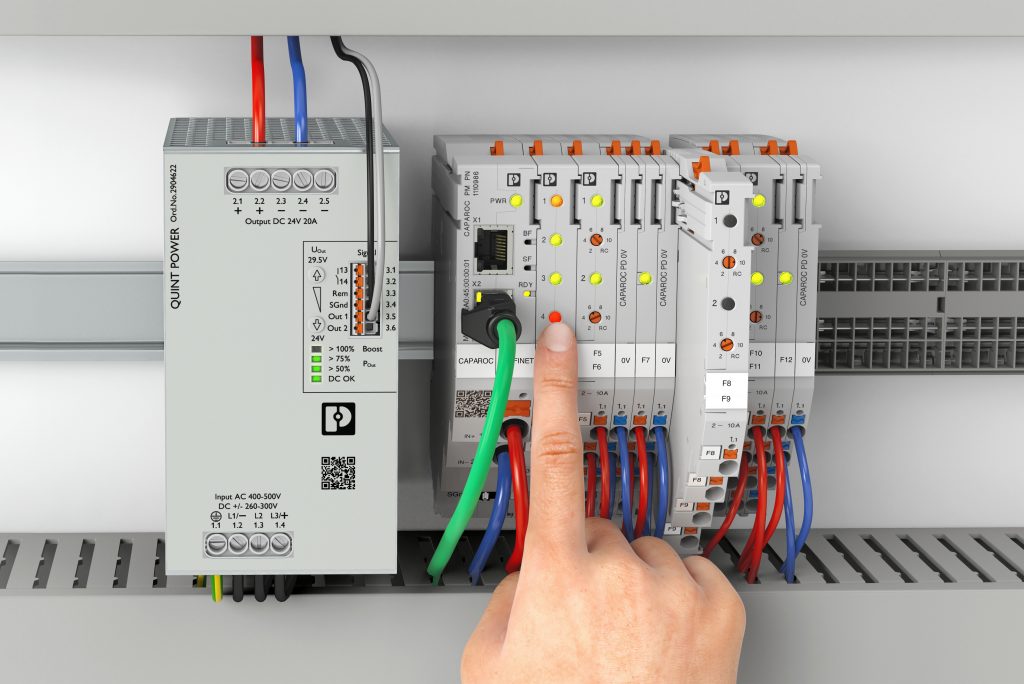

What makes the most amount of your time daily? Assembly? Picking? Wiring? Marking? Testing?

Well, if the answer to that is wiring then we can help you out with some time-saving tools to help streamline your processes.

The CF 3000 will strip and crimp your wires in less than 2secs… 1.2secs to be precise! The time saved on this machine is approx. 4x over a minute. The CF 3000 will strip and crimp wire sizes of 0.25mm, 0.5mm, 0.75mm, 1mm, 1.5mm and 2.5mm that are supplied on a strip of 50pcs.

The CF 1000 will do the same as above, but you can use loose ferrules fed into a hopper on top of the machine. Using air pressure to make the crimp, you can again crimp 0.25mm, 0.5mm, 0.75mm, 1mm, 1.5mm and 2.5mm all in less the 2secs.

If you like keeping the feeling of crimping in the palm of your hand then you can check out the Crimpfox 4in1. This hand tool cuts, strips, twist your strands the crimps for you. Keeping all this in one tool saves you 30% crimping time.

If stripping is all you need then the WF 1000 will strip your cable for you in 0,3secs! Up to 6mm cable size and adjustable stripping length.

If you spend most of your day measuring and measuring cable to cut to size then have a look at the CUTFOX 10. You can cut cables of up to 10mm and set quantities to do so. Walk off and leave to work and you’ll have a pie of cable waiting for you.

How do you cut rail and trunking? If the answer is a hacksaw then check out the PPS Compact and the PPS CD tabletop cutters. These will save you lots and lots of sawing time.

And lastly, our electric torque screwdrivers – the time saver here speaks for themselves and we have two models, one for up to 16 torque settings and the other up to 21.

Talk to us about our impressive range of hand tools today.