Written by James Davies, Warehouse & Assembly Manager

Custom-made Solutions Department- Part 2

Now you have met the team, I would like to introduce some of the custom-made solutions that Phoenix Contact can offer to customers that will help save both time and costs. Many customers are now taking advantage of this service, orders for custom-made products rose by 25% in 2014.

If you are not familiar with the services that we can offer in our Custom-made Solutions Department, read on to find out the benefits that you could receive.

In the Custom-made Solutions Department, are main work involves custom-made rail assemblies, but we can do a varied amount of work including:

- Labelling of individual products

- Made to order marking

- Profile cutting to your measurements

- Cabling with labels

- Made to order production kits

- Tool kits

This is by no means an exhaustive list, so if there is something else that you require, please let us know.

5 Reasons of why you should use Phoenix Contact’s Custom-made Solutions Department:

- We are located in Telford, Shropshire and your order will be completed by a dedicated custom-made solutions team.

- Saves you time and costs by freeing-up your staff members from having to build rail assemblies in-house.

- You will be assigned a direct internal contact person for your customised requirements.

- You will receive a free download of our CLIP Project Advanced Software to design your own rail assemblies. Our Marking & Tools specialist will show you how to design and mark a rail to your specifications.

- The result will be a unique product that is made exclusively for you.

Custom-made Solutions timeline

This is an example of the steps taken to complete a custom-made rail assembly.

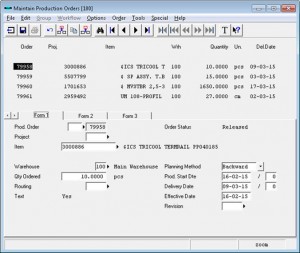

1)  Once a customer has placed an order, it is put onto our ERP BAAN system. This will then allocate a production slot and generate an advised completion date for the customer.

Once a customer has placed an order, it is put onto our ERP BAAN system. This will then allocate a production slot and generate an advised completion date for the customer.

2) By working through a time and motion system, Trevor will then ensure the item will be completed before the customer’s advised date. Once he has the production order paperwork, the first thing he will do is pick the order ready to build the product.

2) By working through a time and motion system, Trevor will then ensure the item will be completed before the customer’s advised date. Once he has the production order paperwork, the first thing he will do is pick the order ready to build the product.

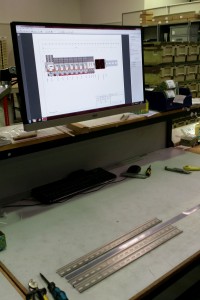

3) Once the order has been picked, the rail has to be measured and cut to size according to the electronic drawing screen.

3) Once the order has been picked, the rail has to be measured and cut to size according to the electronic drawing screen.

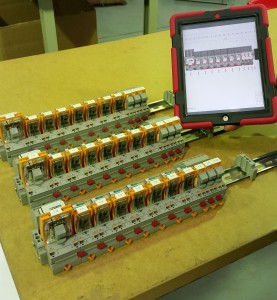

4) Trevor will then build the unique rail for the customer, ensuring the products are assembled in the correct order according to the customer spec drawing.

4) Trevor will then build the unique rail for the customer, ensuring the products are assembled in the correct order according to the customer spec drawing.

5) Once the rail is complete, Trevor will do a pre-inspection ensuring that we maintain very high standards of accuracy.

5) Once the rail is complete, Trevor will do a pre-inspection ensuring that we maintain very high standards of accuracy.

6) The order will then pass through Quality Assurance. Once this is complete, the finished order will be packed and shipped to the customer.

6) The order will then pass through Quality Assurance. Once this is complete, the finished order will be packed and shipped to the customer.

If you are interested in any of our custom-made solutions, please visit our website and complete the contact form.