Are you thinking of integrating SAFETY in your Automation System? Let me introduce an easy and viable solution to you… Its PROFISAFE!

PROFIsafe is a certified profile for PROFIBUS and PROFINET. With SIL 3 (safety integrity level) or category 4 according to EN ISO 13849-1, PROFIsafe meets the highest safety requirements for the processing and manufacturing industry. The same cable is used for both safety-related and standard communication.

The following paragraphs will give you technical idea on what PROFIsafe is.

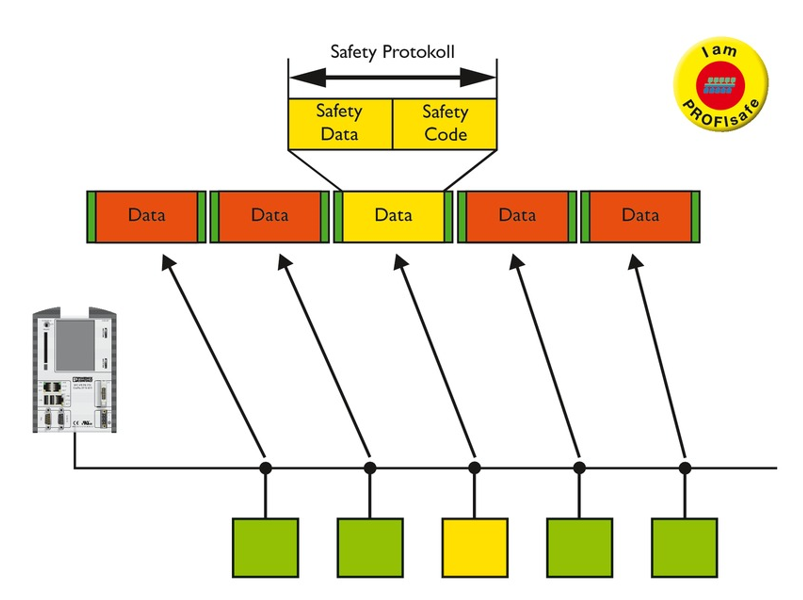

The Protocol

The PROFIsafe system is an extension of the PROFIBUS and PROFINET system. Freely programmable safety functions can be executed with the system and the required safe input and output data can be transmitted from and to the safe I/O devices.

The safe controller and the safe bus devices communicate with one another via the PROFIsafe protocol, which is superimposed on the standard PROFIBUS or PROFINET protocol and contains the safe input and output data as well as data security information.

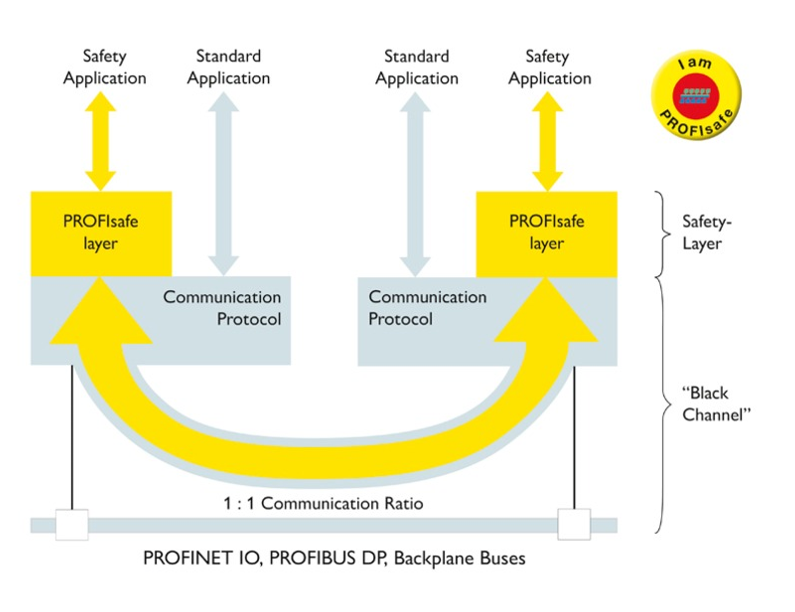

The Black Channel Principle

Just like INTERBUS-Safety, PROFIsafe uses the black channel principle to transmit safe data via a standard network.

The safe data, consisting of purely safety-related user data and the protocol overhead required for protection, is transmitted via PROFIBUS or PROFINET together with non-safety-related data.

The F-Host in the safe controller and the F-Device in the I/O module exchange safe signals in this way.

The integrated safety mechanisms protect against the following possible errors:

- Repetition of messages

- Loss of messages

- Insertion of messages

- Incorrect order of messages

- Data corruption

- Delay of messages

- Recurring memory errors in switches

- Mix up of devices

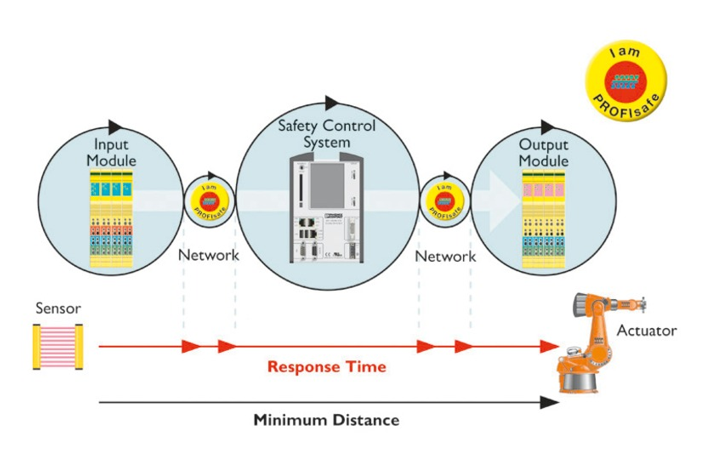

The Response Time

The minimum distance between the safety equipment and hazard depends on the following factors:

- Delay time of the sensor

- Processing time of the safety program in the safety controller including network transmissions

- Processing and filter times in the input and output modules

- Delay or lag time of the actuator

The delay times of the sensors and actuators are independent of the safety protocol used and must be considered separately.

Due to free-running, unsynchronised individual processes, the response time is determined as the sum of the following values:

- Watchdog time of the input module

- Set watchdog time of the network from the input module to the controller

- Set watchdog time of the safe controller

- Set watchdog time of the network from the controller to the output module

- Watchdog time of the output module

Want to find out more? Feel free to contact us at marketing@phoenixcontact.com.sg!